Modernizing the U.S. Navy through Digital Engineering Tools and the Digital Thread

As we enter "decade of maximum danger," modernization and sustainment of defense systems must achieve rapid readiness for warfighter missions

02-08-2024

02-08-2024

Barbara Supplee

Barbara Supplee

DIGITAL ENGINEERING

DIGITAL ENGINEERING

Key Takeaways:

- The digital transformation of the U.S. Navy is not merely a technological evolution but a strategic imperative for maintaining maritime dominance in the 21st century.

- Digital engineering's low-risk virtual environment and digital threads provide agile engineering and decision-making to reduce cost early and often and vet design decisions holistically across the full system lifecycle.

- The Department of Defense has made digital engineering a mandatory strategic imperative for how its components design, develop, deliver, operate and sustain defense systems.

LISTEN TO THIS BLOG:

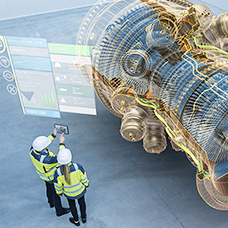

Current U.S. Navy and Marine Corps priorities call for the fleet and force to modernize by innovating expeditiously and efficiently at the speed of relevance to strengthen maritime dominance. The modernization and sustainment of existing hardware, systems, programs and infrastructure is complex. Factors such as budget, availability of trained and certified personnel, capacity and reliance on legacy software and digital information systems impede transformation. One crucial aspect of this transformation lies in the integration of modern digital engineering tools, with the digital thread emerging as a key enabler for innovation and efficiency and which serves as a prime example of how software is driving technology advancement.

Digital engineering (DE) encompasses a broad spectrum of technologies and methodologies created to streamline the design, development and maintenance of complex systems. Critical to DE are tools that facilitate collaboration among various stakeholders, enhance data-driven decision-making and significantly reduce development cycles. In particular, the use of DE tools ensures rapid insertion of emerging technology into systems while maintaining high technology readiness levels. Additionally, the establishment of a digital thread seamlessly integrates the solutions created from those tools and connects data across each phase of a system's lifecycle.

The mission application of DE and DE tools across system lifecycles is demonstrated by the fact that the Department of Defense has made digital engineering a mandatory strategic imperative for how its components design, develop, deliver, operate and sustain defense systems. In December 2023, the Office of the Undersecretary of Defense for Research and Engineering issued DoD Instruction (DoDI) 5000.97 establishing policy, assigning responsibilities and providing procedures for implementing and using digital engineering.

Per the policy, “ ...DoD will use digital engineering methodologies, technologies and practices across the lifecycle of defense acquisition programs, systems, and systems of systems to support research, engineering, and management activities. Digital engineering must be addressed in the acquisition strategy, including how and when digital engineering will be used in the system lifecycle and expected benefits of its use. In addition, as specified in DoDI 5000.88, certain programs must include a digital engineering implementation plan in the systems engineering plan.” The new directive also states that DE capability must “connect the phases of the acquisition lifecycle, allowing feedback and flow of information across acquisition activities and processes,” citing a DE ecosystem and digital thread as capability elements.

One of the primary advantages of DE tools is their ability to enhance the design process. Advanced computer-aided design (CAD) software allows for the creation of highly detailed and accurate models, enabling naval engineers to visualize, test and refine their designs in a low-risk virtual environment. These tools also allow engineers to employ automation to enforce critical design rules and process rigor. This not only accelerates the design phase but also reduces the likelihood of errors, ensuring that the final product meets the Navy's expressed requirements.

An example is SAIC’s support of the Navy’s MK 48 Heavyweight Torpedo Afterbody/Tailcone and Fuel Tank Programs. We have leveraged cloud-based DE tools and integration expertise to create an approach that provides a single authoritative source of truth easing decision-making, facilitating more effective and successful testing and enhancing communication as the program and customer teams view the same material at the same time.

Industry partners such as SAIC incorporate best-in-class technologies into integrated, mission-oriented, open-architecture solutions. With strengths in systems integration coupled with modern digital tools and ready-now integration space, SAIC utilizes a cloud-based DE ecosystems and non-proprietary data models to develop a digital thread for delivering solutions that are simple, user-friendly and available for engineering teams and stakeholders to use on day one, including our ReadyOne DE ecosystem and digital thread solution, which received Business Intelligence Group’s 2024 BIG Innovation Award. This is a strategic imperative as the Navy and Marine Corps move toward what Gabriel Collins and Andrew S. Erickson call the “decade of maximum danger” in their book "U.S.-China Competition Enters the Decade of Maximum Danger," as modernization and sustainment must achieve rapid readiness for warfighter missions without sacrificing availability.

The digital thread’s utility extends beyond design by providing a continuous flow of connected data throughout the entire lifecycle of a system. This allows for real-time monitoring, rapid impact analysis, predictive maintenance and efficient upgrades. For the Navy, this means increased readiness, reduced downtime and a more agile response to emerging threats.

In the realm of hardware modernization, the digital thread plays a pivotal role in supply chain management. By digitally connecting manufacturers, suppliers and maintenance facilities, the Navy can optimize logistics, mitigate parts-obsolescence risks, minimize delays and ensure a steady supply of critical components. This not only enhances operational efficiency but also contributes to cost savings over the long term.

Additionally, DE tools facilitate more collaboration among different departments and organizations involved in naval modernization efforts while protecting the intellectual property of the supply chain. The ability to share data seamlessly promotes cross-disciplinary innovation, allowing experts in various fields to contribute their expertise to a project. This collaboration fosters a culture of continuous improvement and adaptability, which are crucial elements for staying ahead in a rapidly changing geopolitical landscape.

The digital transformation of the Navy is not merely a technological evolution but a strategic imperative for maintaining maritime dominance in the 21st century. To do so, the Navy must capitalize on industry’s decades of system integration expertise to enable system-of-systems modularity and optimization to harmonize disparate systems and create efficiencies in cost and operations that ultimately aid innovation at the speed of relevance.

The gains and heightened readiness afforded by the integration of modern DE tools and the implementation of a robust digital thread will help position the Navy to not only adapt to current challenges but also to lead in shaping the future of maritime warfare by fielding more effective systems faster and more efficiently.

Learn more about how we support customers with solutions and capabilities for Digital Engineering at SAIC's Digital Engineering page.