Saves precious resources to create unexpected efficiencies

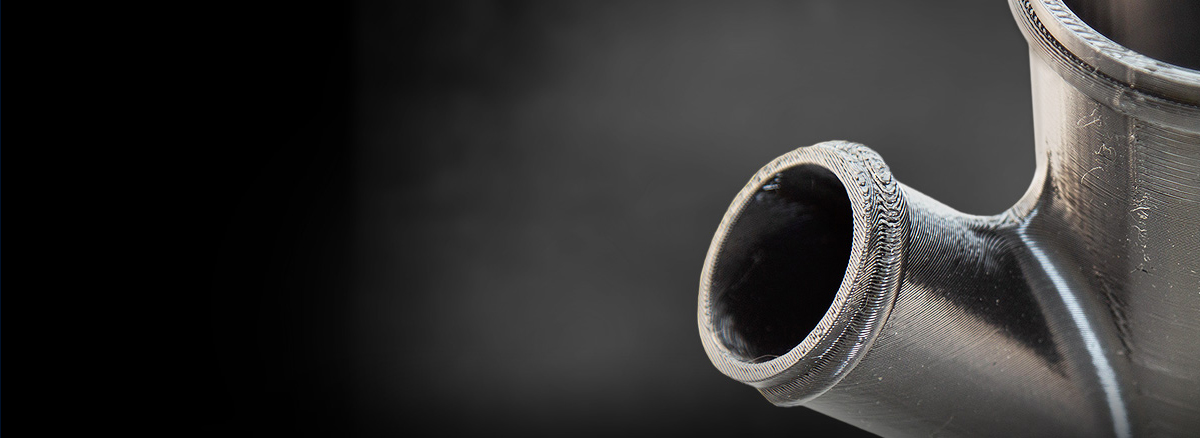

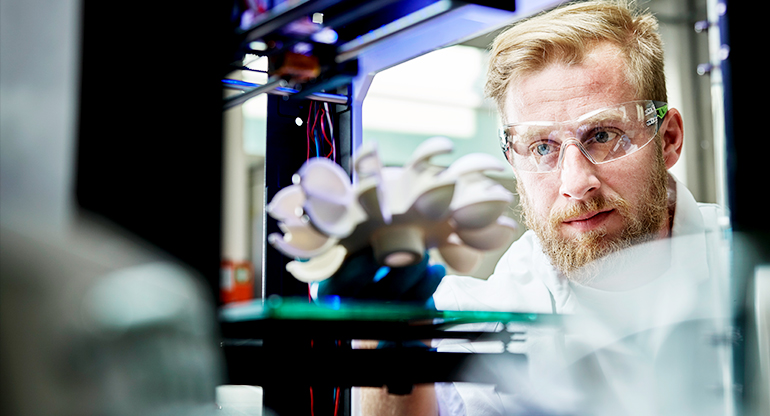

The words “Build Complete” flash on the screen as the prototype engineer carefully retrieves the finished part from the machine. Eric Smay’s advanced engineering team has just finished creating an internal combustion engine air intake that optimizes engine airflow and air intake sensor positioning during engine dynamometer testing. But sheet metal wasn’t utilized to fabricate this intake box. Minute layers of aerospace-grade polymers were extruded, one on top of another, to create the finished product in SAIC’s additive manufacturing lab.

SAIC uses additive manufacturing—or 3D printing—to create a variety of components and parts for an equally wide range of applications across our customer base. Mounting brackets, computer stands, soldering aids, and component prototypes are just a few of the many parts made in our facility. Additive manufacturing ultimately consumes less time and money than traditional manufacturing methods by reducing the steps to make a finished product.

“The end result being … where the supply chain is entirely controlled under a single roof, with only raw materials being procured,” said Smay, systems engineering director, working with the additive manufacturing lab.

From the ground up

3D printing became a hot topic in the early 2000s, but the technology has been around since the 1980s, used primarily in industrial manufacturing and rapid prototyping. It was a quick, accurate technology that cost far less than alternative methods.

As the term implies, additive manufacturing builds parts quite literally from the ground up. The 3D printer deposits raw material layer by layer, transforming a 3D model from a computer into a tangible object. Traditional manufacturing works in the exact opposite way, subtracting and modifying raw material to arrive at the same end product, but this requires a lot more time and material.

As 3D printing matured and its processes were refined, one thing remained clear: Additive manufacturing cost significantly less money, generated less waste, and consumed fewer working hours when manufacturing a comparable end product.

Its value was proven, and SAIC adopted this technology to provide our customers with more affordable mockups and products.

Pushing the limits for our customers

Today, SAIC leverages additive manufacturing to support the military’s combat vehicle programs. Smay and other SAIC engineers constantly push the limits of our 3D printers, developing novel prototype and component variants that redefine the possibilities of additive manufacturing. Reducing cost, lead time, and weight is invaluable to America’s military in fulfilling its mission, and additive manufacturing cuts the consumption of those resources into fractions.

The capabilities of additive manufacturing are accelerating, so keeping pace and remaining at the leading edge is no easy feat. It’s a challenge Smay and the team understand and face daily while remaining committed to providing our customers with the best total quality solutions.

“The at-the-edge nature of our design contains inherent levels of risk as new technologies and innovative concepts are incorporated. Additive manufacturing is one tool available to our team to mitigate these risks,” Smay said.

Dream big

As with any technology, additive manufacturing has its limitations. The end product is only as big as the printing bay.

But our team is putting in the hours to bring larger and more complex solutions to life.

“This technology is moving very quickly, and the industry is working to address many of the concerns over repeatability and available materials,” Smay said.

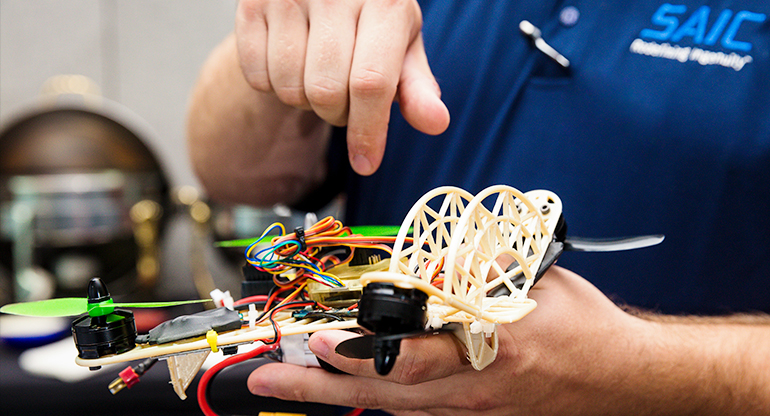

Traditional manufacturing cannot create the unique structures and geometric shapes additive manufacturing makes into reality. Imagination alone may soon be the only limitation on the scope of products designed through additive manufacturing.

“Intricate lattice and hollow structures can now be realized with little concern over the quality and cost constraints associated with conventional manufacturing methods,” Smay said.

SAIC has never been afraid of pushing the limits. As larger printers are released and multi-material manufacturing becomes a reality, more SAIC applications and solutions are beginning their life cycles in the bay of a 3D printer.