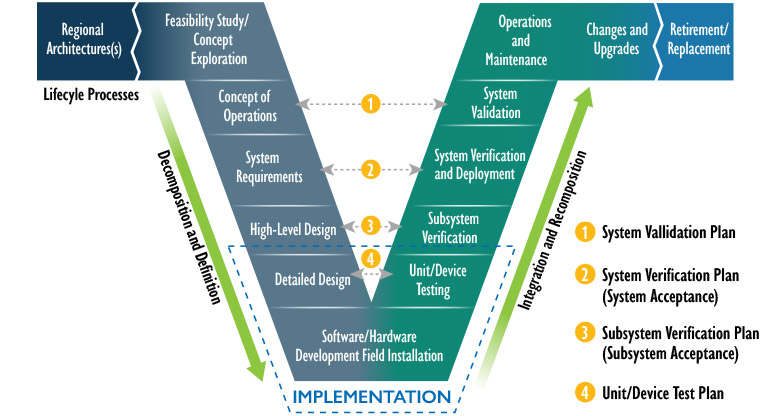

As federal contractors and practitioners explore artificial intelligence in engineering, interest often gravitates toward the high-profile applications: AI that designs the next fighter jet, automatically generates system architectures or optimizes component configurations. Those all happen during the design and development phase of the systems engineering lifecycle, which engineers call the “left side of the V” (see Figure 1).

Focusing solely on design and development neglects a critical economic reality. For any platform or system, sustainment engineering activities represent the longest-lasting phase and generate the highest total cost. While hype focuses on headline-grabbing design applications, the real competitive advantage—along with the most significant cost savings—can be gained by applying AI throughout the entire systems engineering lifecycle.

AI can help optimize designs for better long-term performance and cost efficiency. It’s also valuable in reducing total lifecycle cost by improving operations and sustainment without compromising operational availability. Indeed, AI-powered capabilities are uniquely able to help engineers solve the longstanding challenge of complex, multidimensional optimization.

As shown in Figure 1, the systems engineering V-model maps the complete lifecycle of complex “systems of systems” used in defense and civilian platform design. The left side, representing design and development, typically spans years. The right side, covering sustainment and operations, is typically measured in decades and accounts for 60% to 80% of a system’s total lifecycle cost. Most AI digital engineering investments have clustered on the left side, leaving significant opportunities to pursue optimization on the “right side of the V” after systems are deployed.

Programs and agencies that successfully operationalize AI for digital engineering across the lifecycle will gain advantages that compound over time.

Automate and Innovate: Three Paths to Success

When delivering AI for digital engineering, SAIC recommends automating and innovating across the systems lifecycle—and offers three paths to success.

Path 1: Legacy Data Integration

Using our ReadyOneAI solution, we’ve already slashed TDP review time from months to 80% completion in just minutes. |

Most engineering programs don’t start from scratch. In fact, SAIC supports many organizations whose programs have significant legacy data that must first be migrated and integrated. Such work may involve an established system that has begun to degrade and needs to be updated, modernized or otherwise improved for the mission. The challenge is that legacy data, including technical data packages (TDPs), is unstructured and scattered across disparate systems. Traditional approaches require engineers to manually organize this chaos before any meaningful work can begin. But agentic AI can change this equation by automating data ingestion, structuring and organization. Using our ReadyOneAI solution, we’ve already slashed TDP review time from months to 80% completion in just minutes.

In addition to being more efficient, automating data capture and analysis accelerates speed to value. When engineers can immediately access structured, organized historical data, they can make informed design decisions and tradeoffs from day one instead of spending months on archaeological data recovery. And, without the cognitive load associated with processing and analyzing data, engineers can focus more on higher-order problem-solving and innovation.

Path 2: Generative Design

The second path focuses on the more widely publicized application of generative design—that is, using AI to automatically create optimized solutions. When parameters are properly defined, AI can generate architecture models from requirements, create mechanical hardware designs and optimize for multiple variables simultaneously, such as weight, strength, cost-effectiveness and performance requirements, to name a few.

Generative design goes beyond simple automation. AI can also explore design spaces that would take human engineers months to investigate, testing thousands of permutations to find optimal solutions that might never occur to human designers working within traditional constraints.

Path 3: Predictive Analysis

The third path focuses on the right side of the V: the sustainment, operations and maintenance phases that last the longest and cost the most. As always, the goal is to maintain systems operating at or near 100% availability while ensuring they perform within their defined parameters across decades of service.

Sustainment benefits immensely from AI-powered predictive maintenance that maximizes operational availability and AI-enabled performance optimization that ensures systems operate within their design envelope for mission success. By moving toward AI-driven maintenance and analysis, it becomes possible to shift from reactive to predictive maintenance models. A more proactive approach ensures that systems are maintained at optimal performance, reduces unplanned downtime and extends the operational lifespan of the systems. Ultimately, it provides the win-win scenario of improved mission readiness alongside significant cost savings.

The Digital Thread Connecting It All

What makes a full-spectrum approach powerful is more than the individual applications of AI. It’s how they connect via a digital thread—the continuous flow of data that links every phase of a system’s lifecycle. This thread serves as both connector and foundation. Without it, organizations get only one piece of the puzzle, limiting their ability to fully exploit AI and machine learning capabilities.

The digital thread enables upstream and downstream impact analysis that was previously impossible. For instance, when a component change is proposed during sustainment, AI can instantly trace the impacts back through original design requirements and forward through operational performance predictions. Similarly, when field data reveals unexpected performance patterns, AI can feed that information back to improve future designs.

The digital thread also enables systems to become genuinely adaptive. As mission parameters change (a constant reality in contested environments), systems become more agile and can adjust their performance profiles based on AI analysis of new requirements without taking platforms offline for physical modifications.

Capture the Real AI Advantage with Mission Integration

The real AI advantage in digital engineering lies not in designing the perfect system, but in continuously optimizing it throughout its operational life. Organizations that master a full-spectrum approach will deliver better outcomes at lower costs while adapting faster to changing requirements. That represents a decisive advantage in an era of evolving threats and rapid technological change.